Table of Contents

What is a Goods Received Note (GRN)?

A Goods Received Note (GRN) is an official receipt that documents the delivery of goods from a supplier and its receipt by the buyer. Upon delivery of the goods, the supplier provides a GRN to the buyer to confirm that the goods have been delivered and are satisfactory to all parties.

A GRN includes important information like an outline of goods delivered, the prices and quantities, the name of the vendor and more. A GRN is only applicable for tangible goods, and not intangible services provided by vendors.

GRN is a part of the larger procurement process, involving multiple stakeholders, cross-functional approvals, deadlines and tedious manual tasks. With automated solutions like RazorpayX Source to Pay, businesses are able to manage GRNs, invoices, PRs and POs with transparency and ease.

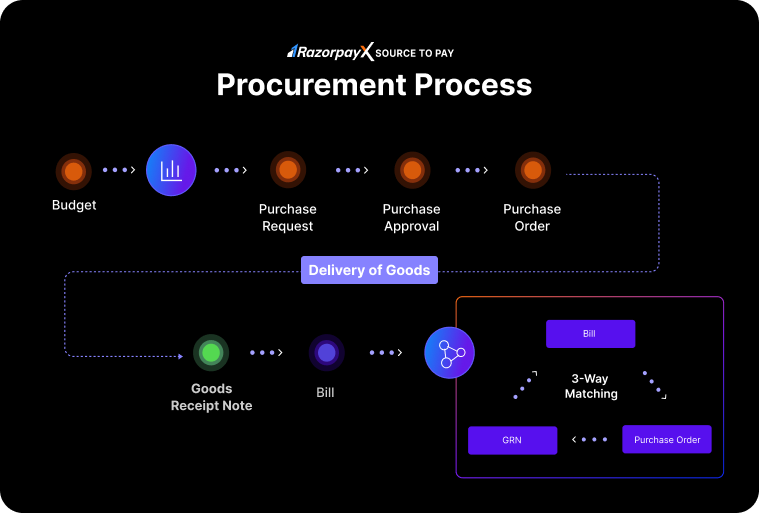

GRN in the Procurement Process

The procurement process is multi-stage and cross-functional. A GRN is used in the procurement process to verify and confirm the quantity and quality of goods delivered by cross-checking against a purchase order. It is sent along with the invoice, or bill.

The finance team also uses the GRN to conduct 3-way matching between the GRN, bill and purchase order.

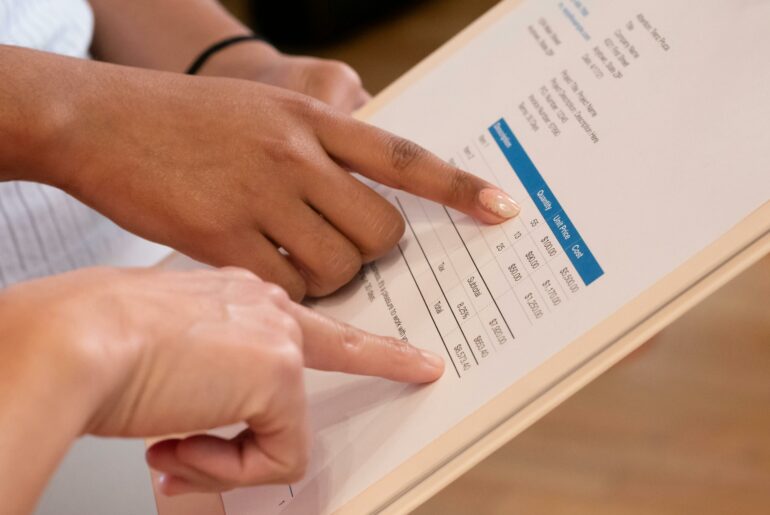

Components of a Goods Receipt Note

Components of a Goods Receipt Note

A Goods Received Note (GRN) acts as a receipt for delivered goods, ensuring everything matches the original order. Here’s a breakdown of its key components:

- Header: This section includes essential details like the company name, a unique GRN number, and the date of receipt.

- Supplier Information: Identifies the supplier by including their name, address, and contact details.

- Delivery Details: Captures information about the delivery itself, such as the date and time, mode of transport (truck, airfreight, etc.), and any delivery notes or special instructions.

- Itemized List: The heart of the GRN, this section provides a detailed list of all received items. It includes:

- Product Description: A clear description of each item.

- Quantity: The exact number of units received for each item.

- Unit Price: The price per unit as agreed upon in the purchase order.

- Total Value: The calculated total cost for each item (quantity multiplied by unit price).

- Item Codes: Any relevant product codes or reference numbers used for internal tracking.

- Quality Check Section (Optional): While not always included, some GRNs have a section for noting any discrepancies in quality or damage upon arrival.

- Signatures: Authorized personnel from both the receiving company and the supplier (or their delivery representative) sign the GRN to acknowledge receipt and verification of the delivered goods.

Importance of a GRN

The Goods Received Note (GRN) plays a vital role in ensuring smooth and accurate procurement. Here’s why it’s important:

Verifying Quality and Quantity of Goods

A GRN helps the procurement and requesting departments to verify that the quality and quantity of goods delivered pass their quality criteria and standards. This helps prevent disagreements and potential disputes with suppliers.

Read more: Procurement Software

Dispute Resolution

The GRN serves as documented evidence for resolving disputes with suppliers in case of discrepancies between what was ordered and what was delivered. This is why it’s important to carefully check the GRN against the goods delivered before confirming receipt of the order.

3-Way Matching

3-way matching is a verification process that acts like a secure payment gateway, comparing three key documents before approving an invoice:

- Purchase Order (PO): This outlines the agreed-upon order details with the supplier, including quantity, price, and specifications.

- Goods Received Note (GRN): This confirms the actual quantity and condition of the goods received from the supplier.

- Supplier Invoice: This details the amount the supplier is requesting for the delivered goods.

Only when all three documents match (quantities, prices, etc.) is the invoice approved for payment. This process helps prevent errors, catches discrepancies, and minimizes the risk of overpaying for goods or services.

Inventory Management

The GRN provides crucial data for updating warehouse inventory records. By documenting received items, businesses can maintain accurate stock levels and avoid stockouts or overstocking.

Drawbacks of Goods Received Note

Here are a few issues with GRNs in the procurement process.

Time-consuming process

The process of creating and processing GRNs can be time-consuming, especially for frequent deliveries or large quantities of items. This can slow down the receiving process and impact efficiency.

Delays due to paperwork

Traditionally paper-based GRNs are prone to errors and can be misplaced. Manual data entry from the GRN into inventory systems can also introduce mistakes.

Further, there are typically three copies of the GRN floating around – one with the procurement department, one with the requesting department and one with the supplier. Managing and maintaining all 3 copies can be quite challenging and can cause delays and errors.

Luckily, there are automated, digital-first solutions like RazorpayX Source to Pay that make GRN management seamless.

Read more: Procurement Analytics

Reliance on PO

The effectiveness of a GRN depends on the accuracy of the initial purchase order. Errors in the PO can carry over to the GRN and lead to discrepancies later.

Automating Goods Receipt Notes

Businesses can significantly improve their procurement process by automating tasks like GRN generation and data entry. This eliminates manual processes that are time-consuming and prone to errors.

Automation ensures faster and more accurate verification of received goods, streamlining inventory management and reducing the risk of overpayments.

RazorpayX Source to Pay is changing how businesses handle procurement.

No more paperwork or approval confusions – with Source to Pay, businesses can automate workflows, gain real-time visibility into spending and make smarter purchasing decisions.

Start saving money and time with RazorpayX Source to Pay now.

FAQs

Is a GRN always necessary?

While GRNs are highly recommended for most procurement processes, they might not be essential for every situation. For very small deliveries or low-value items, simpler receiving procedures might suffice. However, for most businesses, the benefits of using GRNs outweigh the drawbacks, especially for maintaining accurate records and mitigating potential issues.

Who creates a GRN?

The responsibility of creating a GRN typically falls on the receiving department within a company. This could be the warehouse staff, receiving clerks, or any personnel authorized to accept deliveries. They will verify the delivered goods against the purchase order and then create the GRN document.

What happens to a GRN after it's created?

Once the GRN is completed and signed by both parties (receiving company and supplier), it goes through a few steps: Internal Approval: The receiving department might need internal approvals within the company before finalizing the GRN. This could involve managers or the finance department. Matching and Payment: The GRN becomes a key part of the three-way match process. It's compared with the purchase order and the supplier's invoice to ensure everything aligns before payment is authorized. Record Keeping: The GRN is then stored electronically or as a physical document for future reference. It serves as a record of the specific delivery and can be helpful for audits or resolving discrepancies

Can GRNs be automated?

Absolutely! Traditional paper-based GRNs are prone to errors and can be time-consuming. Many businesses are now adopting automated GRN systems. These systems integrate with procurement software and allow for electronic recording of deliveries, reducing manual data entry and streamlining the verification process.